Posted on 4th Dec 2023

Soft starters and variable frequency drives (VFDs) are both devices used in the control and protection of electric motors. While they serve different purposes, they can indeed improve operations and enhance applications in various ways.Check out Darwin Motion - VFD & Servo Drive manufacturer article below

Reduced Mechanical Stress: Soft starters are designed to gradually ramp up the voltage and current to the motor during startup, avoiding the sudden torque and stress associated with direct-on-line starting. This results in reduced mechanical stress on the motor and connected equipment.

Extended Motor Life: By minimizing the stress during startup, soft starters can contribute to the extended life of motors and associated mechanical components.

Energy Savings: Soft starters help in controlling the starting current, which can reduce power demand and energy consumption during motor start-up.

Speed Control: VFDs allow for precise control of the motor speed by adjusting the frequency and voltage supplied to the motor. This is especially useful in applications where varying speeds are required, such as in pumps and fans.

Energy Efficiency: VFDs can significantly reduce energy consumption by adjusting the motor speed to match the actual load requirements. Motors running at reduced speeds consume less energy.

Soft Start and Stop: VFDs also provide soft start and stop functions, gradually ramping up or down the motor speed, reducing stress on the system.

Process Optimization: VFDs enable better control over industrial processes by allowing for fine-tuning of motor speed, leading to improved efficiency and productivity.

Integration with Automation Systems: Both soft starters and VFDs can be integrated into larger automation and control systems, providing enhanced monitoring and control capabilities.

Fault Detection and Protection: These devices often come with built-in protection features, such as overload protection, short circuit protection, and phase unbalance protection, contributing to improved system reliability.

Maintenance Savings: The use of soft starters and VFDs can contribute to lower maintenance costs due to reduced wear and tear on motors and associated equipment.

Energy Cost Savings: By optimizing motor performance, both in terms of starting and running, these devices can contribute to lower energy costs over time.

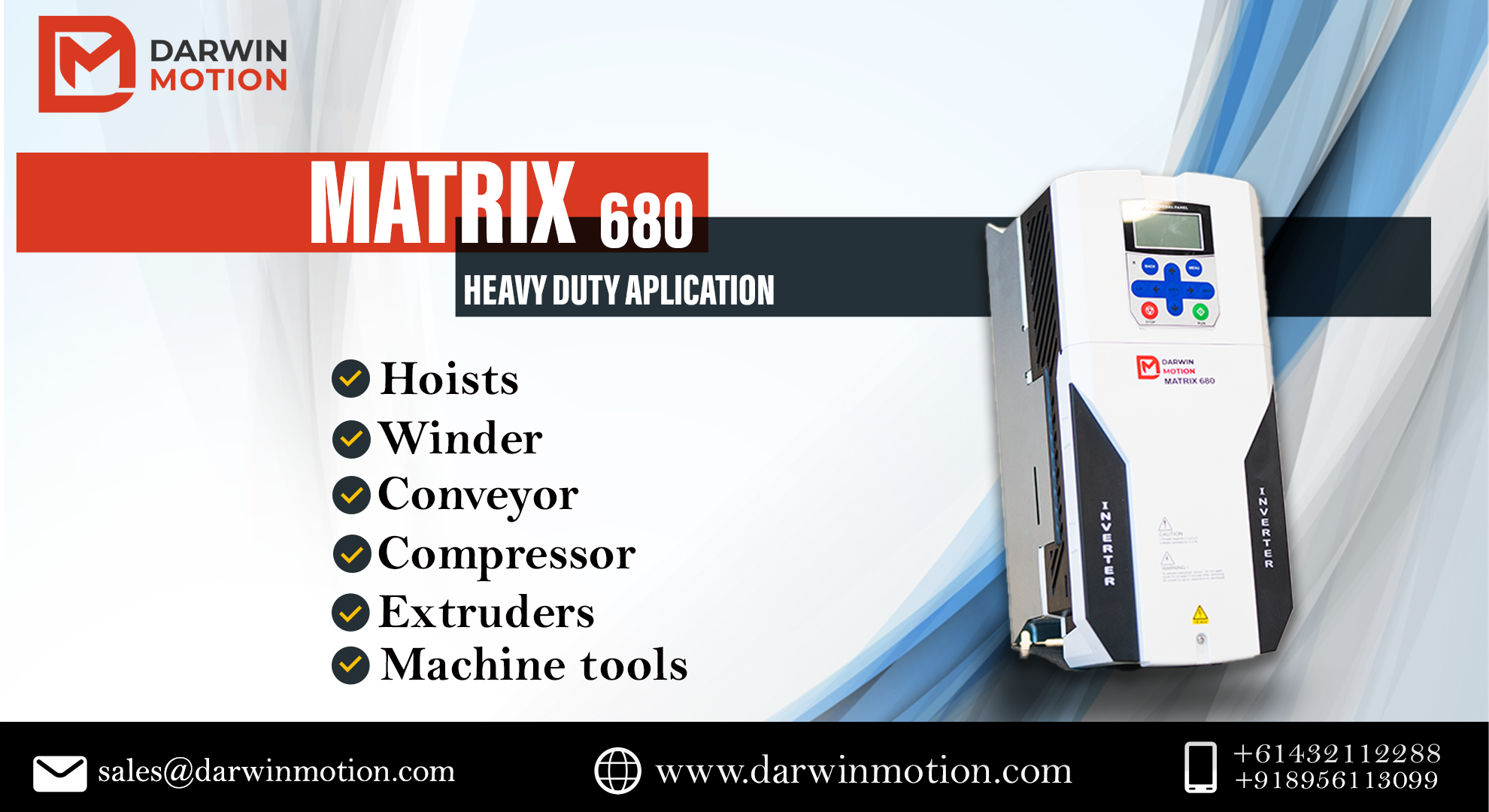

In summary, while soft starters are more focused on reducing mechanical stress during startup, Darwin Motion VFDs such as Micro Drive- Matrix 900, DR Matrix 350 / Solar Drive, High Frequency Drive - DR Matrix 500, High Performance Drive - DR Matrix 680, Regenerative Drive - DR Matrix 880 offer broader benefits by allowing for variable speed control and energy savings. Depending on the specific requirements of your application, using one or a combination of both can indeed improve operations and provide long-term benefits.