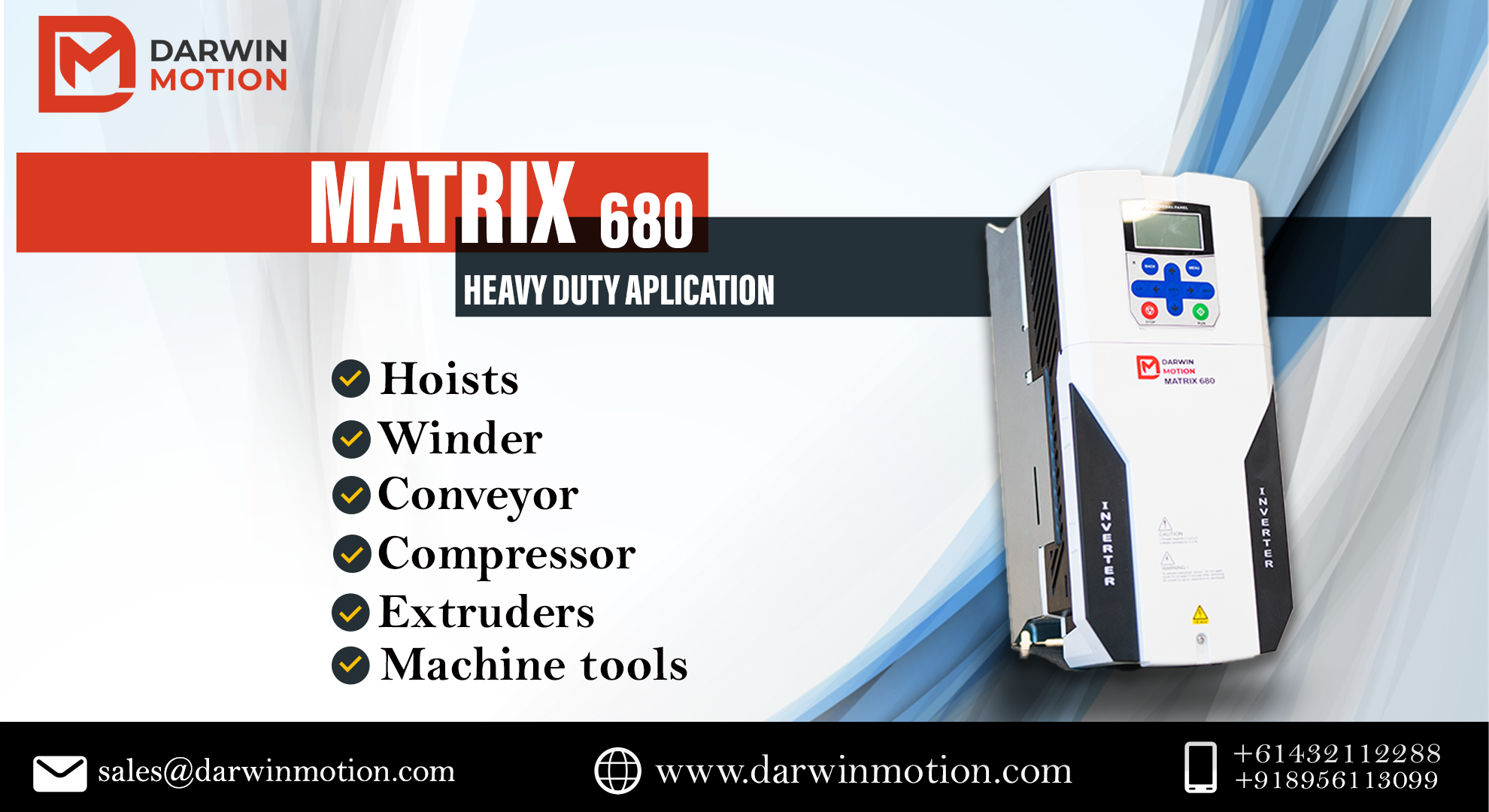

The Darwin Motion Matrix 680 drive provides the Compact combination of power, ease of use, flexibility, and performance.

THINGS TO CHECK BEFORE CHOOSING VARIABLE FREQUENCY DRIVES

| Model Code | Rated Value | General Load Application | Heavy Load Application | Noise Level | Heat Radiation | Air Volume | Dimension | ||||

In(A) | Imax(A) | ILd(A) | PLd(kW) | IHd(A) | PHd(kW) | dBA | W | M3/h | |||

4.8 | 6 | 4.5 | 0.75 | 2.5 | 0.37 | 45 | 40 | 53 | F1 | ||

7.5 | 10 | 7 | 1.5 | 4.5 | 0.75 | 45 | 94 | 53 | |||

11 | 15 | 10 | 2.2 | 7 | 1.5 | 45 | 172 | 53 | |||

15 | 20 | - | - | 10 | 2.2 | 45 | 232 | 53 | |||

| Model Code | Rated Value | General Load Application | Heavy Load Application | Noise Level | Heat Radiation | Air Volume | Dimension | ||||

In(A) | Imax(A) | ILd(A) | PLd(kW) | IHd(A) | PHd(kW) | dBA | W | M3/h | |||

5.2 | 7 | 5 | 1.5 | 2.5 | 0.75 | 45 | 40 | 53 | F1 | ||

6.3 | 9 | 6 | 2.2 | 4.2 | 1.5 | 45 | 76 | 53 | |||

10.5 | 15 | 9.8 | 4 | 5.6 | 2.2 | 45 | 97 | 53 | |||

14 | 20 | 13.5 | 5.5 | 10.5 | 4 | 45 | 172 | 53 | |||

18.2 | 25 | 17.5 | 7.5 | 14.5 | 5.5 | 45 | 210 | 53 | |||

26 | 36 | 25 | 11 | 17.6 | 7.5 | 45 | 325 | 55 | F2 | ||

28 | 35 | 26 | 15 | 25 | 11 | 45 | 420 | 55 | |||

41 | 57 | 38.6 | 18.5 | 35 | 15 | 57 | 550 | 145 | F3 | ||

48 | 67 | 46 | 22 | 41 | 18.5 | 57 | 660 | 145 | |||

63.5 | 89 | 61 | 30 | 48 | 22 | 57 | 890 | 145 | |||

78 | 109 | 75 | 37 | 66 | 30 | 60 | 1114 | 290 | F4 | ||

95 | 133 | 91 | 45 | 79 | 37 | 60 | 1140 | 290 | |||

120 | 168 | 115 | 55 | 94 | 45 | 60 | 1200 | 290 | |||

162 | 227 | 155 | 75 | 116 | 55 | 60 | 1440 | 350 | F5 | ||

185 | 222 | 178 | 90 | 160 | 75 | 60 | 1940 | 350 | |||

225 | 270 | 215 | 110 | 179 | 90 | 67 | 2200 | 570 | |||

| Model Code | Rated Value | General Load Application | Heavy Load Application | Noise Level | Heat Radiation | Air Volume | Dimension | ||||

In(A) | Imax(A) | ILd(A) | PLd(kW) | IHd(A) | PHd(kW) | dBA | W | M3/h | |||

272 | 326 | 261 | 132 | 215 | 110 | 68 | 3300 | 685 | F6 | ||

320 | 384 | 310 | 160 | 259 | 132 | 68 | 3850 | 685 | |||

375 | 450 | 360 | 200 | 314 | 160 | 68 | 4100 | 720 | F7 | ||

450 | 540 | 430 | 220 | 387 | 200 | 68 | 4600 | 720 | |||

487 | 584 | 470 | 250 | 427 | 220 | 68 | 5100 | 720 | |||

546 | 628 | 525 | 280 | 481 | 250 | 68 | 5782 | 1200 | F8 | ||

624 | 718 | 600 | 315 | 550 | 280 | 68 | 6252 | 1200 | |||

686 | 789 | 660 | 355 | 616 | 315 | 68 | 7866 | 1200 | |||

760 | 874 | 730 | 400 | 671 | 355 | 68 | 9100 | 1300 | F9 | ||

865 | 995 | 830 | 450 | 759 | 400 | 68 | 9900 | 1300 | |||

950 | 1093 | 920 | 500 | 850 | 450 | 68 | 10500 | 1680 | |||

1100 | 1265 | 1080 | 560 | 950 | 500 | 68 | 11500 | 1680 | |||

1200 | 1380 | 1150 | 630 | 1060 | 560 | 68 | 12600 | 1680 | |||

| Model Code | Rated Value | General Load Application | Heavy Load Application | Noise Level | Heat Radiation | Air Volume | Dimension | ||||

In(A) | Imax(A) | ILd(A) | PLd(kW) | IHd(A) | PHd(kW) | dBA | W | M3/h | |||

22 | 44 | 21 | 18.5 | 18 | 15 | 57 | 550 | 290 | F4 | ||

26 | 54 | 25 | 22 | 22 | 18.5 | 57 | 660 | 290 | |||

35 | 64 | 33 | 30 | 27 | 22 | 57 | 890 | 290 | |||

44 | 70 | 41 | 37 | 35 | 30 | 60 | 1114 | 290 | |||

49 | 71 | 48 | 45 | 45 | 37 | 60 | 1140 | 290 | |||

61 | 104 | 58 | 55 | 52 | 45 | 60 | 1200 | 290 | |||

80 | 124 | 80 | 75 | 65 | 55 | 60 | 1440 | 720 | |||

220 | 240 | 215 | 200 | 175 | 160 | 68 | 4100 | 720 | F6 | ||

271 | 320 | 245 | 220 | 220 | 200 | 68 | 4600 | 720 | |||

290 | 350 | 265 | 250 | 250 | 220 | 68 | 5100 | 720 | |||

| Model Code | Rated Value | General Load Application | Heavy Load Application | Noise Level | Heat Radiation | Air Volume | Dimension | ||||

In(A) | Imax(A) | ILd(A) | PLd(kW) | IHd(A) | PHd(kW) | dBA | W | M3/h | |||

430 | 520 | 420 | 400 | 385 | 355 | 68 | 9100 | 1300 | F82 | ||

470 | 655 | 455 | 450 | 430 | 400 | 65 | 9900 | 1300 | |||

522 | 700 | 505 | 500 | 470 | 450 | 68 | 10500 | 1300 | |||

590 | 800 | 571 | 560 | 555 | 500 | 68 | 11500 | 1300 | |||

721 | 820 | 710 | 630 | 600 | 560 | 68 | 12600 | 1300 | |||

900 | 1350 | 880 | 800 | 680 | 630 | 68 | 16000 | 1680 | F92 | ||

1160 | 1750 | 1115 | 1100 | 900 | 800 | 68 | 20000 | 1680 | F104 | ||

1250 | 2000 | 1250 | 1250 | 1114 | 1100 | 68 | 26000 | 1680 | |||

1350 | 2200 | 1400 | 1400 | 1250 | 1250 | 68 | 32000 | 1680 | |||

| Name | Country/Language | Download | File Type |

| Technical Catalogue | English | ||

| Technical Specification | English |