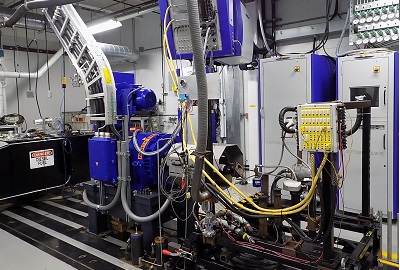

The power dynamometer adopts AC variable frequency feedback loading, and the loaded energy is fed back to the grid through the load generator, instead of simple thermal energy consumption, which greatly reduces energy efficiency costs, which is the main theme of the dynamometer industry Routine test items: temperature rise, noise, vibration test, load test, fatigue test, energy efficiency test, performance test, dynamic balance correction, no-load running-in, power generation test, power test, etc. Involved equipment: engines, motors, gearboxes, reducers, powertrains, drive shafts, bearings, hydraulic stations, drives and other occasions that require energy transmission