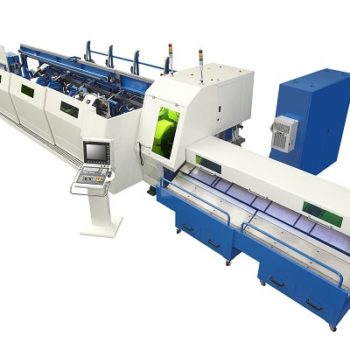

Cross Cutter Metal Cutting line, also known as Kaiping shearing line, uncoiling line and transverse shearing line, is used to uncoiling, leveling, sizing, cutting into flat sheets of required length and stacking them. It is suitable for processing cold-rolled and hotrolled carbon steel, silicon steel, tinplate, stainless steel and various metal materials after surface coating.

Darwin Motion, renowned variable frequency drive manufacturers, provide cutting-edge VFD solutions for cross-cutter metal cutting applications. Explore precision and efficiency in your operations with our top-quality VFDs A standard production line includes storage table, feeding trolley, auxiliary support, uncoiler, telescopic shovel head, leveler, looper, side guide, sizing machine, shearing machine, conveyor, stacking frame, discharging Trolley composition. The specific configuration can be customized according to customer needs, which belongs to non-standard customized equipment.

Overall Darwin Motion Vfds can help to improve the efficiency, accuracy, and safety of cross-cutter metal cutting applications.

Darwin Motion Matrix Drive can be used in various applications within the CROSS-CUTTER METAL CUTTING process to provide control and efficiency. Here are some possible areas where VFDs can be used: