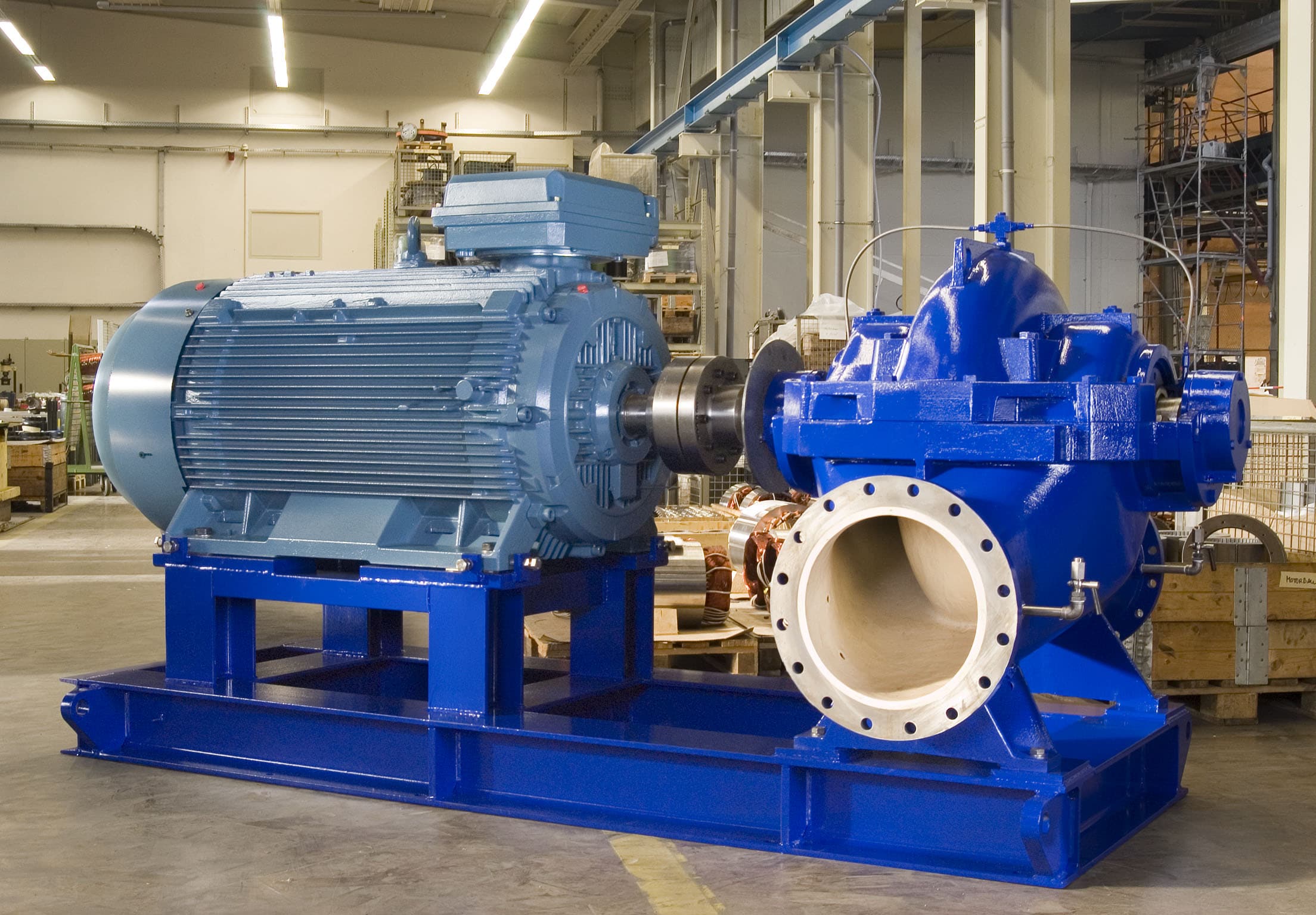

A multi-pump VFD (Variable Frequency Drive) application is a system that uses multiple pumps controlled by a single VFD to manage the flow of fluid in a process. This type of application is commonly used in industrial and commercial operations, such as water treatment plants, HVAC systems, and fire suppression systems.

Darwin Motion Matrix Drive can be used in multiple pump applications where there are two or more pumps working together to provide a required flow rate. These applications can include:

In all these applications, Darwin Motion drive can be used to control the speed of the pumps, allowing for better control over the flow rate and pressure. This can help to improve energy efficiency, reduce maintenance costs, and extend the life of the pumps.