In the dynamic landscape of industrial automation, Darwin Motion EtherCAT Communication Drives have emerged as a game-changing technology, offering unparalleled speed, precision, and scalability in data exchange and control within manufacturing environments. EtherCAT (Ethernet for Control Automation Technology) represents a high-performance industrial Ethernet standard renowned for its real-time capabilities and flexibility. In this article, we delve into the intricacies of EtherCAT Communication Drives, exploring their functionality, advantages, applications, and future prospects.

EtherCAT is a high-performance Ethernet-based fieldbus system that is commonly used in industrial automation. VFD drives can be equipped with EtherCAT communication capabilities, allowing them to communicate with other devices in the network, such as programmable controllers, sensors, and other drives.

The use of EtherCAT communication in VFD drives provides several benefits, including:

Darwin Motion EtherCAT Communication Drives find application across a diverse range of industrial sectors and use cases, including:

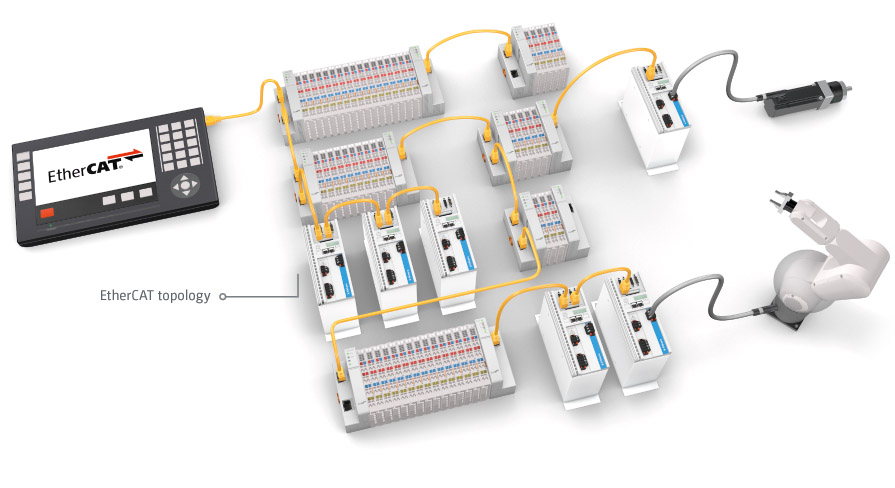

Darwin Motion EtherCAT Communication Drives serve as intelligent motor controllers equipped with built-in EtherCAT interfaces, enabling seamless integration into EtherCAT networks. Unlike conventional communication protocols, EtherCAT employs a unique "processing on the fly" methodology, where data is processed and forwarded in real-time as it passes through each node in the network. This streamlined approach minimizes communication latency, enabling precise synchronization and control of distributed automation systems with microsecond-level accuracy.

At the core of EtherCAT Communication Drives lies the EtherCAT slave controller, responsible for interfacing with the EtherCAT network and executing motion control algorithms. This controller facilitates rapid data exchange between the drive and EtherCAT master devices such as PLCs (Programmable Logic Controllers), HMIs (Human-Machine Interfaces), and motion controllers, enabling coordinated motion control and synchronization across multiple axes.

The adoption of Darwin Motion EtherCAT Communication Drives offers a multitude of advantages, making them indispensable in demanding industrial automation applications:

Darwin Motion EtherCAT Communication Drives represent a paradigm shift in industrial automation, offering unmatched speed, precision, and scalability in motion control applications. With their real-time capabilities, flexible configuration options, and future-ready design, these drives are poised to play a pivotal role in driving the ongoing digital transformation of manufacturing processes and accelerating the realization of Industry 4.0 objectives. As industries continue to embrace advanced automation technologies, EtherCAT Communication Drives will remain at the forefront, empowering manufacturers to achieve new levels of efficiency, productivity, and competitiveness in a rapidly evolving global marketplace.