Posted on 19th Oct 2023

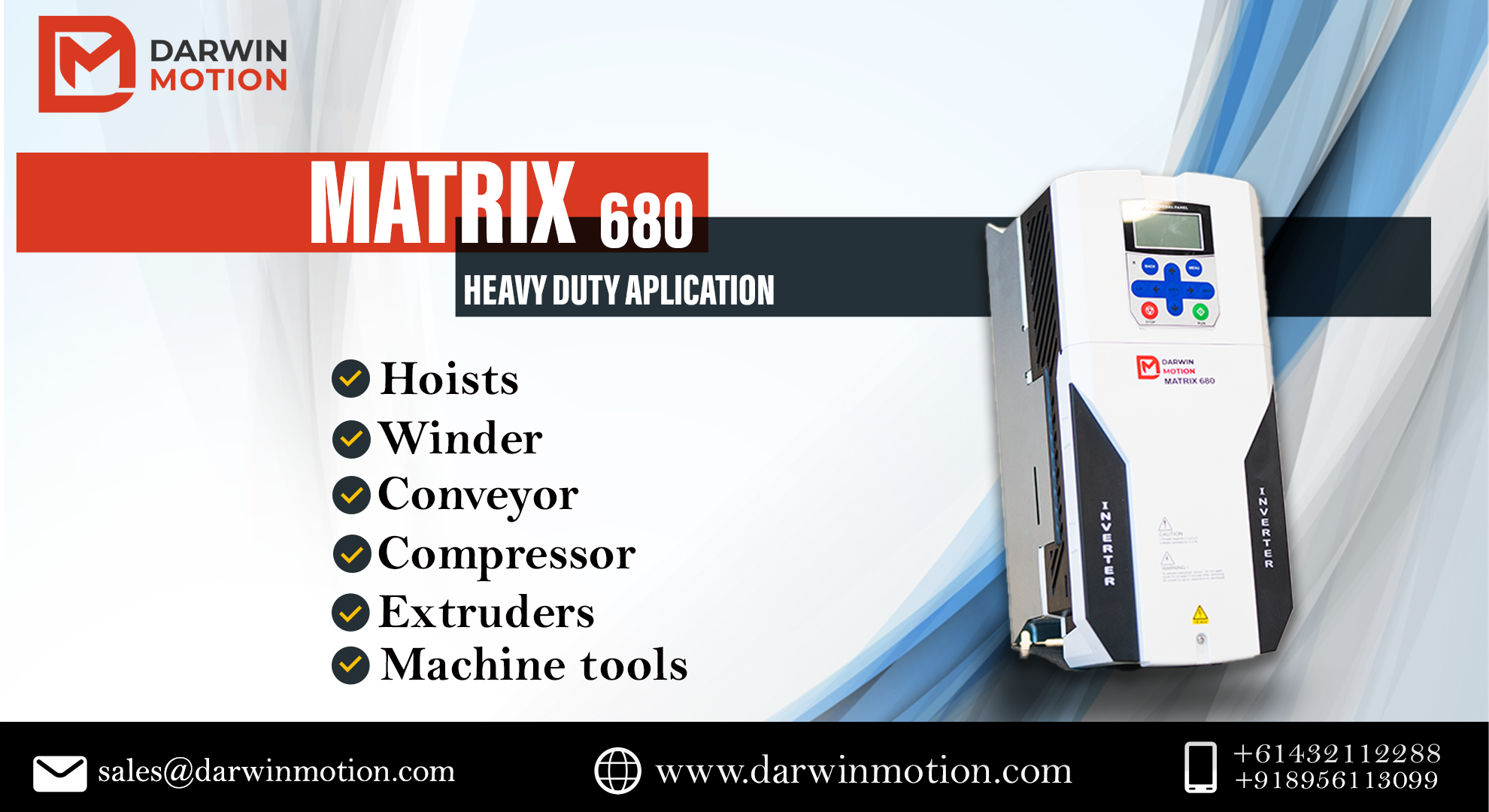

A VFD drive, or Variable Frequency Drive such as Darwin Motion Micro Drive- Matrix 900, DR Matrix 350 / Solar Drive, DR Matrix 500, DR Matrix 680, DR Matrix 880 vfd,servo drive, ac drives, vsd, variable speed drive, inverter, regenerative drive, high performance drive, high frequency drive, is an essential piece of equipment for businesses that rely on automated processes. Unlike a regular motor, a VFD drive can adjust the speed of the motor to ensure optimal performance. This makes them a critical tool for businesses that need to maintain a consistent level of production.

A VFD, or variable frequency drive, is a type of motor controller that allows you to adjust the speed of an AC motor. They are often used in industrial applications, but can also be used in home projects. VFDs are available in a variety of sizes, and can be used to control a wide range of motor sizes.

A variable frequency drive (VFD) is a device that allows the speed of an electric motor to be controlled. This can be helpful in a number of ways, including reducing energy consumption, improving motor efficiency, and protecting equipment.

A VFD Drive can be used in many different applications. Some of the most common applications are in the metal fabrication, plastics, and food and beverage industries. In the metal fabrication industry, a VFD Drive can be used to control the speed of a metal saw. In the plastics industry, a VFD Drive can be used to control the speed of a plastic extruder. In the food and beverage industry, a VFD Drive can be used to control the speed of a food mixer or a beverage mixer.

When selecting a VFD Drive for your application, there are a few things you need to consider. The most important factor is the motor type and power rating. You also need to know the input voltage and frequency, output voltage and frequency, and how much current the drive can handle.

Once you have determined the motor and drive specifications, you can begin to narrow down your choices. Start by comparing the prices of the drives that meet your requirements. Be sure to also compare the features and specifications of each drive.

The final step is to decide which drive is the best fit for your application. Consider the environment where the drive will be used, as well as the required performance and functionality.

To install and commission a VFD drive, the following are required:

-An adequate power supply

-The correct wiring

-A properly sized motor

Once these are in place, the drive can be installed using the manufacturer's instructions. Commissioning typically involves configuring the drive's parameters and testing its functionality.

A VFD drive such as variable speed drive, inverter, regenerative drive, high performance drive, high frequency drive, Micro Drive- Matrix 900, DR Matrix 350 / Solar Drive, DR Matrix 500, DR Matrix 680, DR Matrix 880 requires very little maintenance in order to keep it running smoothly. In fact, most of the time the only thing that needs to be done is to keep the drive clean. It is important to keep any dust or dirt from getting inside the drive, as it can cause damage. Additionally, it is a good idea to check the oil level in the drive once a month and to change the oil every six months.

When troubleshooting a VFD drive, the first step is to identify the issue. There are a number of things that can go wrong with a VFD drive, so it is important to have a good understanding of the drive and its components. Once the issue has been identified, steps can be taken to correct it.

If your business relies on automated processes, then you need a Darwin Motion VFD drive such as Micro Drive- Matrix 900, DR Matrix 350 / Solar Drive, DR Matrix 500, DR Matrix 680, DR Matrix 880. They are essential for maintaining a consistent level of production. Not only do they keep your machines running smoothly, but they can also save you money on energy costs. So if you're looking for a way to improve your operation, consider investing in a VFD drive.